|

Shenzhen Tianweisheng Electronic Co., Ltd.

|

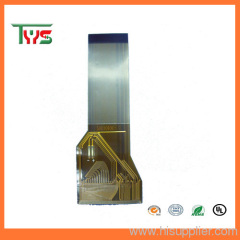

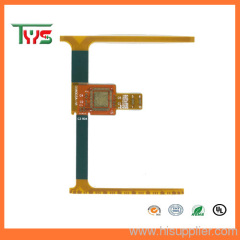

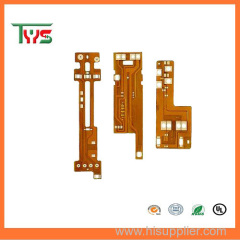

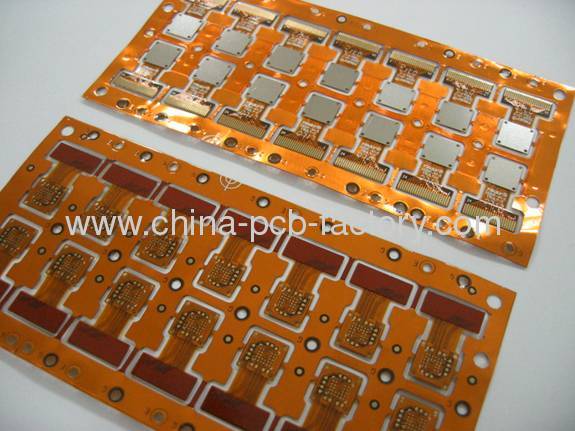

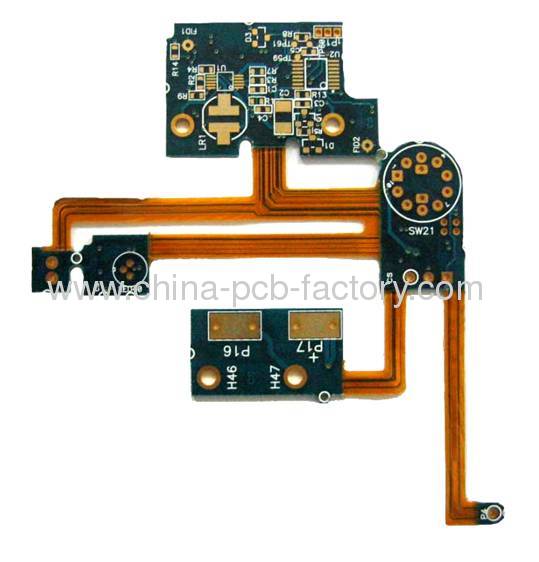

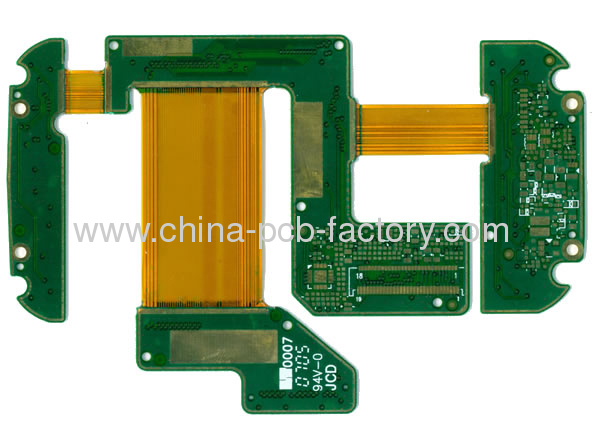

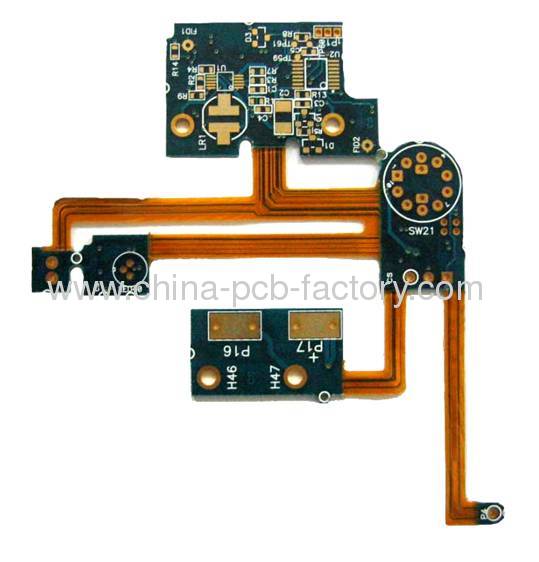

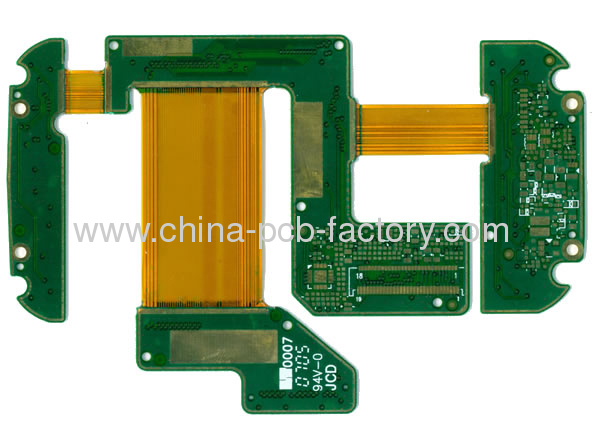

flex pcb design and ssembly

| Price: | 0.02~0.3 USD |

| Payment Terms: | T/T,L/C,WU, |

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

flex pcb design and ssembly

1.15 year experience

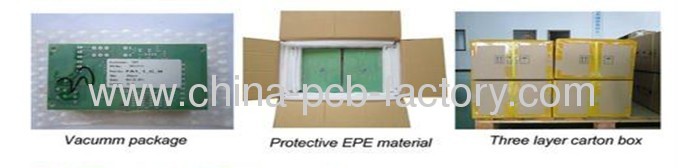

2.Quickly Delivery

3.PCB Clone Copy

4.UL,ROHS,SGS.CE,ISO9001,TS16949

flex pcb design and ssembly

PCB Capacity

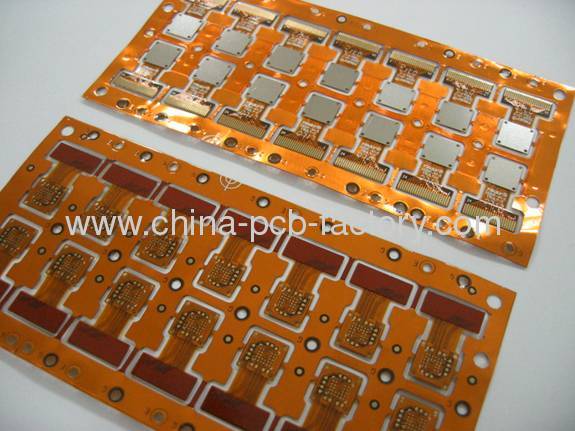

Rigid FPC with 0.2mm Thickness, Yellow Mask, Gold Immersion, 2-Layers

Basic electronic parameters:

1. Manufacturer: RayPCB

2. Original place: Shenzhen China

3. Board material: Polyimide

4. Adhesive: 3M

5. Board thickness: 0.01MM

6. Layer number: 2L

7. Finishing copper size: 1OZ

8. Min line width / track: 0.3MM

9. Min line space / clearance: 0.3MM

10: Min hole / via diameter: 0.2MM

11: Via in plated pad over / VIPPO: No

12. Impedance control: No

13. Coverlay: Yellow

14 Silkscreen: No

15. Surface treatment technology: Gold plated

16: Single size: 2843Mil*2276Mil

Panel size: According to UR GERBER design requirements

17. More special requirements: Need YOUR confirmation

PCB Capacity

NO | ITEM | Technical Data |

1 | Layer | 2-20 Layers |

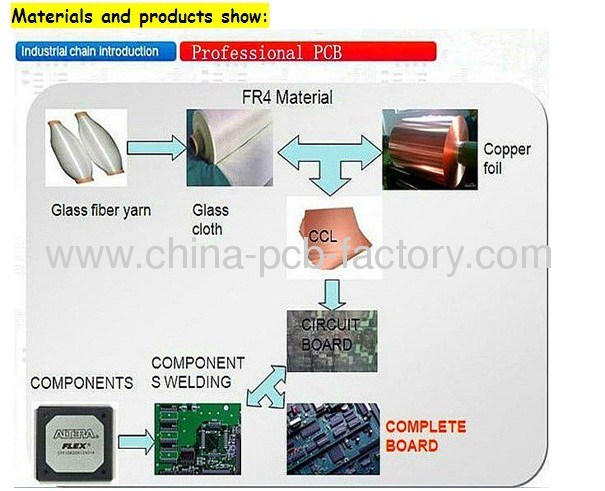

2 | Board material | FR4,FR4 Halogen free,TEFLON Rogers,Getek High-TG(TG>170),Aluminium base |

3 | Max.Board Size0 | 457*660mm |

4 | Min.Board Thickness | 2 layers 0.2mm |

4 layers 0.4mm | ||

6 layers 0.8mm | ||

8 layers 1.0mm | ||

10 layers 1.2mm | ||

5 | Max.Board Thickness | 8.0mm |

6 | Min.Line Width | 0.05mm |

7 | Min.Line Space | 0.05mm |

8 | Min.Hole Size0 | Electroplating Via 0.15mm |

Micro via 0.075mm | ||

9 | PTH Wall Thickness) | 20-25um |

10 | Max.finish copper thickness0 | 8OZ |

11 | PTH Dia.Tolerance | ±0.05mm |

12 | NPTH Dia.Tolerance | ±0.025mm |

13 | Hole Position Deviation | ±0.05mm |

14 | Outline Tolerance | ±0.1mm |

15 | Min.S/M Pitch | 0.08mm |

16 | Insulation Resistance | 3x10Sec, 288°C |

17 | Warp and Twist | ≤0.7% |

18 | Electric Strength | >1.3KV/mm |

19 | Peel Strength | ≥1.4N/mm |

20 | Solder Mask Abrasion | ≥6H |

21 | Flammability | 94V0 |

22 | Impedance Control | ±5% |

RayMing specializes in the PCB manufacturing of Rigid FPC with 0.2mm Thickness, Yellow Mask, Gold Immersion, 2-Layers.

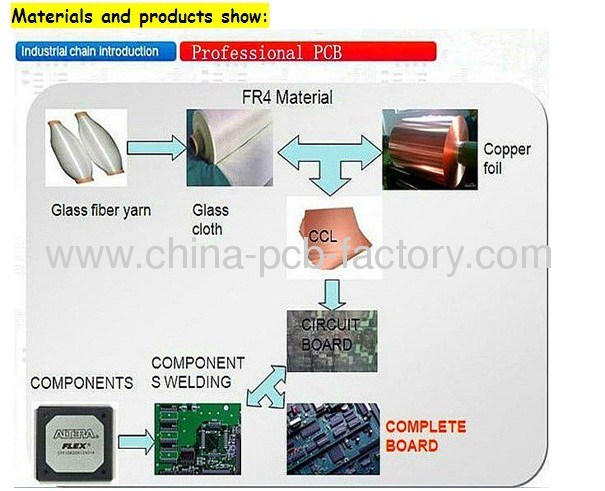

Main business: single-sided; double-sided and multilayer printed circuit boards (up to 40Layer); and some high end boards. e.g. high-frequency circuit boards; HDI boards with Buried & Blind Via PCB; Flex PCB; Flex-Rigid PCB; Single-sided and Double-sided Aluminum boards with high Thermal conductivity.

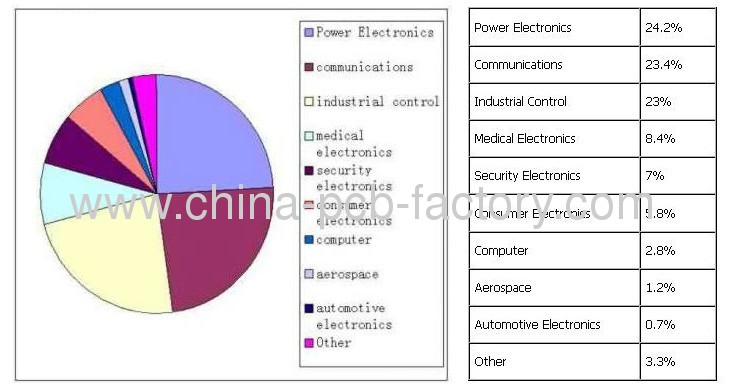

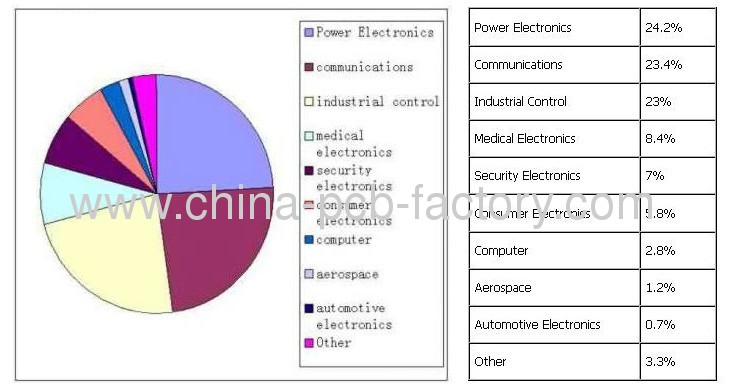

Our products are widely use in power supplies, computers, comunications, optoelectronics, industrial instruments, engineer control, automobile and other consumer electronics.

Also, one-stop business of manufacturing PCB+PCB assembling+helping to purchase components, we'll serve for you.

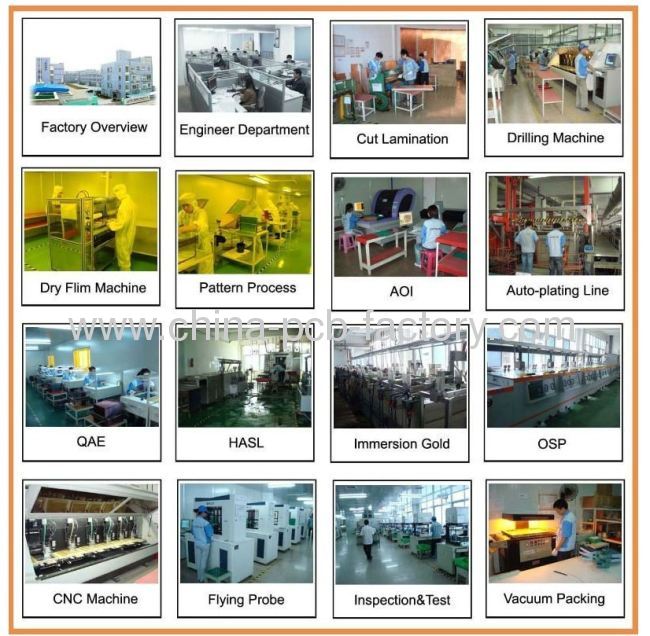

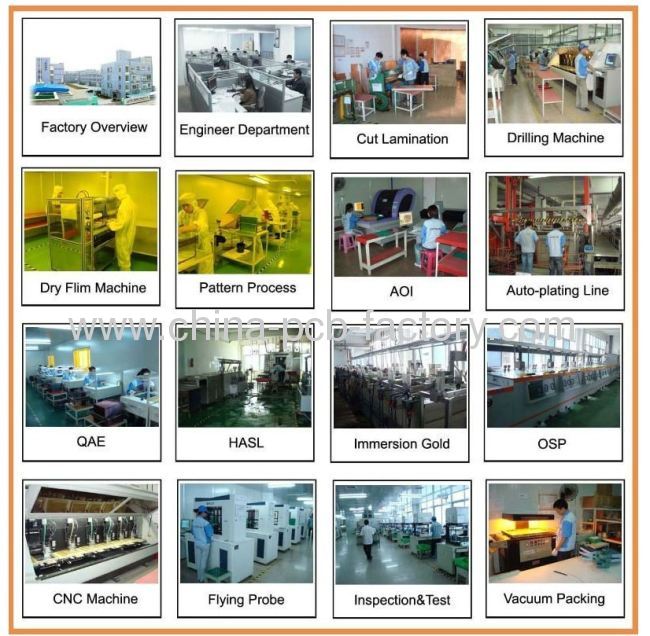

We equipped with advance Processing Equipments and Measurement Techniques, such as: High Pecision CNC Drilling Machines, AOI Tester, German Flying Probe Testers and other advanced equipments, and High Frequency Board manufacturing, Special Impedance Control, Buried & Blind Via manufacturing, Flying Probe Test techniques.

Our customers mainly focus on North and South Americas; Europe; Australiasia; Russian and so on.

Any queries, just contact VIKEY-----vikey720729(Skype)

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!