|

Shenzhen Tianweisheng Electronic Co., Ltd.

|

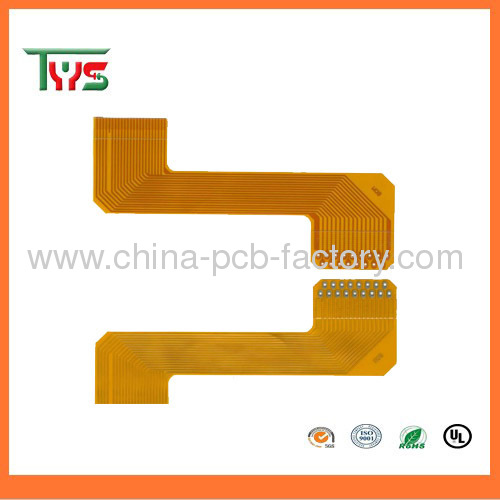

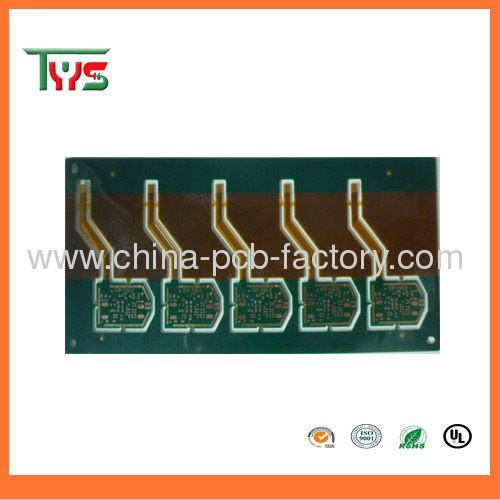

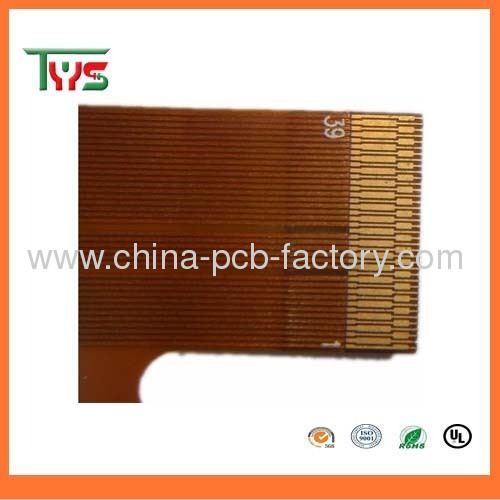

flexible pcb for ledstrip

| Price: | 0.1~0.5 USD |

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

flexible pcb for ledstrip

1. Over 15 years' manufacturing experience

2. Assembly provided

3. 100% quality tested before shipment

4. ISO 9001.

flexible pcb for ledstrip

· processing layers:1-6 layers

· Finished thickness (thinnest): 3mil (0.08mm)

· Minimum aperture: 4mil (0.10mm)

· Minimum line width / spacing: 2 mil (0.05mm)

· Maximum board size: 10 "x 45" (250x 1200mm)

· Surface Treatment: OSP, HASL, Electric Nickel / Gold, , Chemical nickel / gold, lead-free HASL, Immersion Gold

· Insulation resistance: ± 1011Ω (Normal Normal

· Thermal shock resistance: 260 °C 10 sec.

· Processing materials: polyimide (PI), polyester (PET), polyimide (PI) + FR4

Technical requirement:

1) Professional Surface-mounting and Through-hole soldering Technology

2) Various sizes like 1206,0805,0603 components SMT technology

3) ICT(In Circuit Test),FCT(Functional Circuit Test) technology.

4) PCB Assembly With UL,CE,FCC,Rohs Approval

5) Nitrogen gas reflow soldering technology for SMT.

6) High Standard SMT&Solder Assembly Line

7) High density interconnected board placement technology capacity.

Quote requirement:

- Gerber file of the bare PCB board

- BOM (Bill of material) for assembly

- To short the lead time, please kindly advise us if there is any acceptable components substitution.

- Testing Guide & Test Fixtures if necessary

- Programming files & Programming tool if necessary

- Schematic if necessary

OEM/ODM/EMS Services for PCBA:

- PCBA, PCB assembly: SMT & PTH & BGA

- PCBA and enclosure design

- Components sourcing and purchasing

- Quick prototyping

- Plastic injection molding

- Metal sheet stamping

- Final assembly

- Test: AOI, In-Circuit Test (ICT), Functional Test (FCT)

- Custom clearance for material importing and product exporting

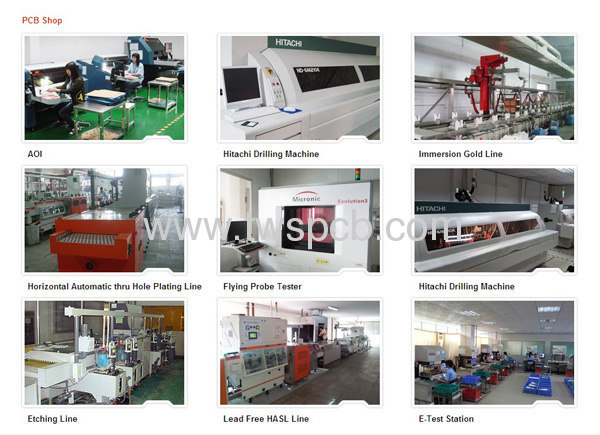

Orientronic PCB assembly Equipment:

- SMT Machine: SIEMENS SIPLACE D1/D2 / SIEMENS SIPLACE S20/F4

- Reflow Oven: FolunGwin FL-RX860

- Wave Soldering Machine: FolunGwin ADS300

- Automated Optical Inspection (AOI): Aleader ALD-H-350B

- Fully Automatic SMT Stencil Printer: FolunGwin Win-5

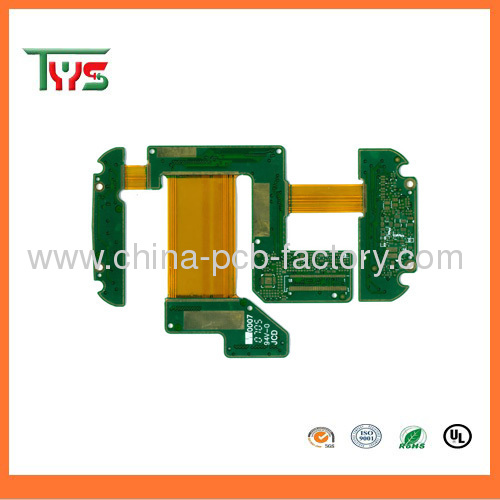

A Solution to a packaging problem

Flexible circuits allow unique designs which solve interconnection problems.

The formability of a flexible circuit enables a package size reduction.

A Flexible circuit makes installation and repair practical and costeffective.

The formability of a flexible circuit enables a package size reduction.

A Flexible circuit makes installation and repair practical and costeffective.

Reduce assembly costs

Flex circuits can be tested prior to assembly of components.

Eliminationof connectors and solder joints reduce costs.

Replacement for a circuitboard and wires

Eliminationof connectors and solder joints reduce costs.

Replacement for a circuitboard and wires

Flex circuits simplify system design.

Flex circuits reduce the number oflevels of interconnection required in an electronic package.

Flexiblecircuits eliminate human error common in wire assemblies as routing isdetermined by artwork and repeatability is guaranteed.

Flex circuits reduce the number oflevels of interconnection required in an electronic package.

Flexiblecircuits eliminate human error common in wire assemblies as routing isdetermined by artwork and repeatability is guaranteed.

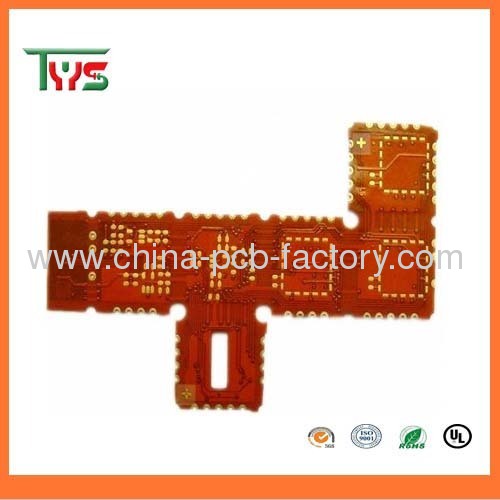

Reduce weight and space

Considerable weight reduction is a benefit over wire harnesses.

Thicknesscan be as thin as .004 inches (.10mm) in total.

Capacity of pcb

Thicknesscan be as thin as .004 inches (.10mm) in total.

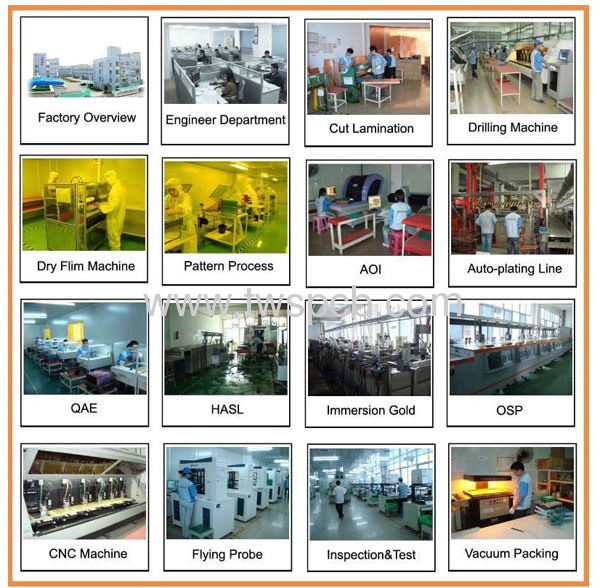

Shenzhen Tianweisheng Electronic Co., Ltd is a professional FPCmanufacturer, with the ability of 1 - 18 layers of PCB and 1-6 layers of FPCproduction. Our businessrange covers from PCB & PCBA design and copy, PCB manufacture to Electroniccomponents purchasing andPCB Assembly. Our products are widely used in communication apparatus,automobile electronics,computers, medical devices, network devices and consumer electronics classfields. Welcome to send us yourinquiry.

NO | ITEM | Technical Data |

1 | Layer | 2-20 Layers |

2 | Board material | FR4,FR4 Halogen free,TEFLON Rogers,Getek High-TG(TG>170),Aluminium base |

3 | Max.Board Size0 | 457*660mm |

4 | Min.Board Thickness | 2 layers 0.2mm |

4 layers 0.4mm | ||

6 layers 0.8mm | ||

8 layers 1.0mm | ||

10 layers 1.2mm | ||

5 | Max.Board Thickness | 8.0mm |

6 | Min.Line Width | 0.05mm |

7 | Min.Line Space | 0.05mm |

8 | Min.Hole Size0 | Electroplating Via 0.15mm |

Micro via 0.075mm | ||

9 | PTH Wall Thickness) | 20-25um |

10 | Max.finish copper thickness0 | 8OZ |

11 | PTH Dia.Tolerance | ±0.05mm |

12 | NPTH Dia.Tolerance | ±0.025mm |

13 | Hole Position Deviation | ±0.05mm |

14 | Outline Tolerance | ±0.1mm |

15 | Min.S/M Pitch | 0.08mm |

16 | Insulation Resistance | 3x10Sec, 288°C |

17 | Warp and Twist | ≤0.7% |

18 | Electric Strength | >1.3KV/mm |

19 | Peel Strength | ≥1.4N/mm |

20 | Solder Mask Abrasion | ≥6H |

21 | Flammability | 94V0 |

22 | Impedance Control | ±5% |

FLEXIBLE PCB FOR LEDSTRIP

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!