|

Shenzhen Tianweisheng Electronic Co., Ltd.

|

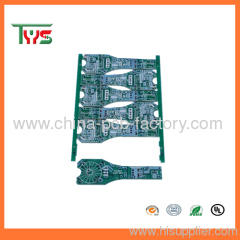

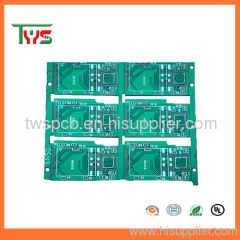

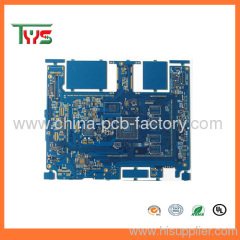

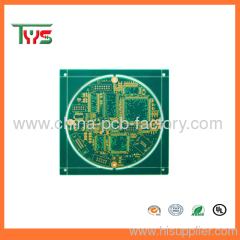

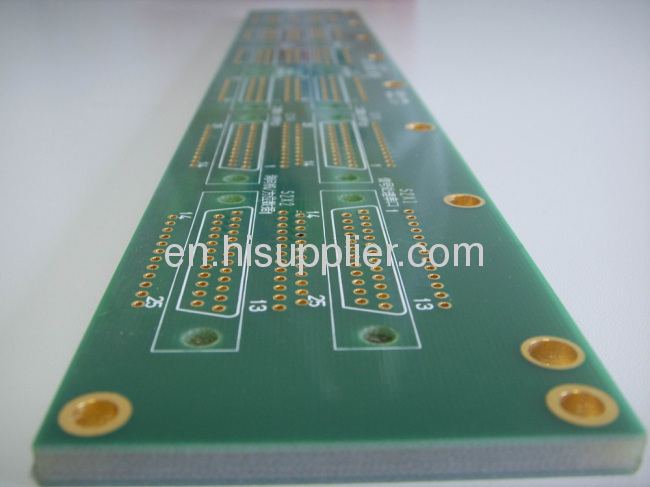

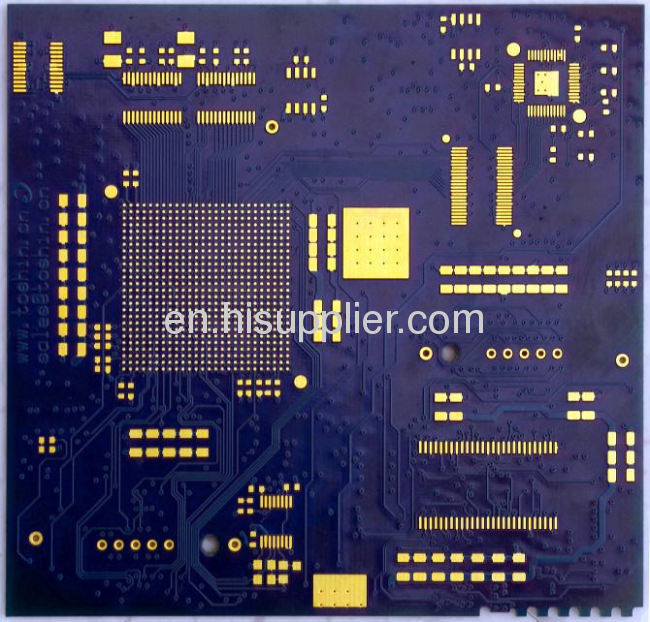

blank printed circuit board

| Price: | 0.1~1.0 USD |

| Payment Terms: | T/T,WU;Paypal |

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

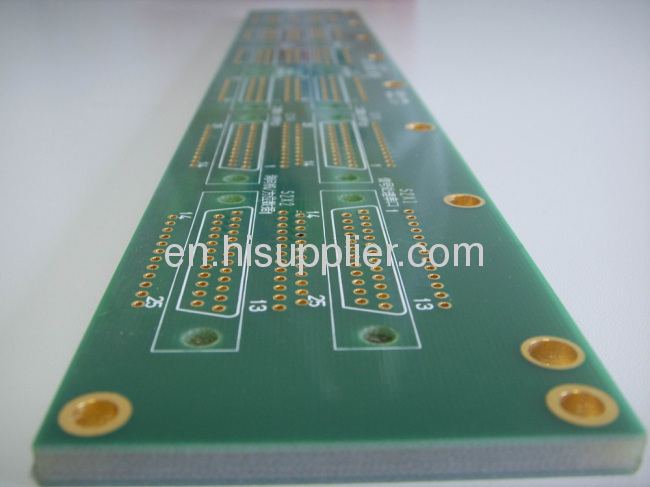

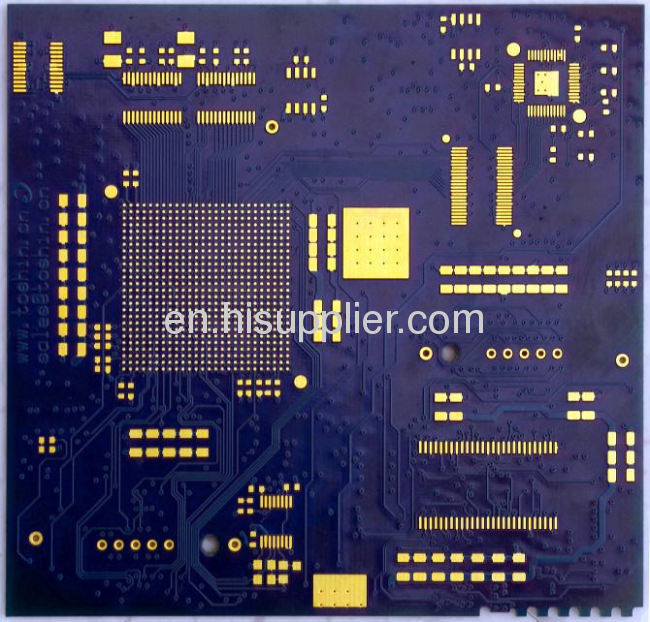

blank printed circuit board

1.15 years manufacturer experience

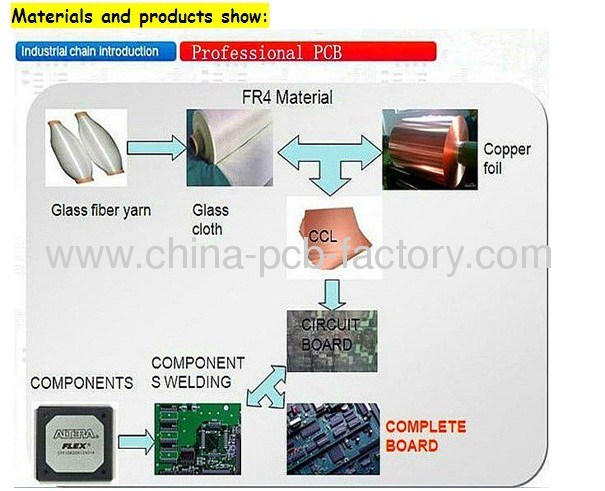

2,FR-4 94v0 material

3,specialized in pcb

5 China manufacturer

blank printed circuit board

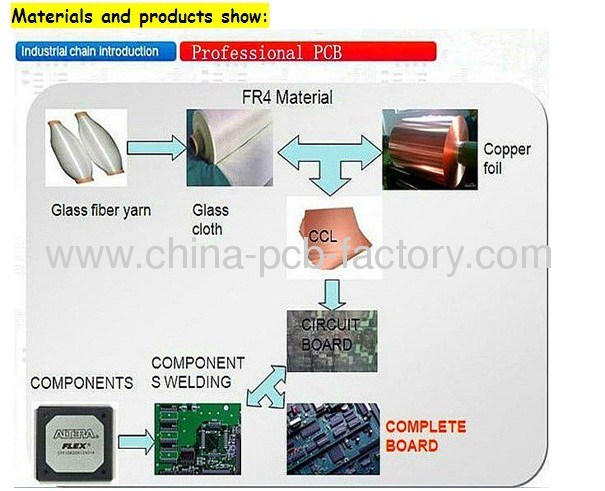

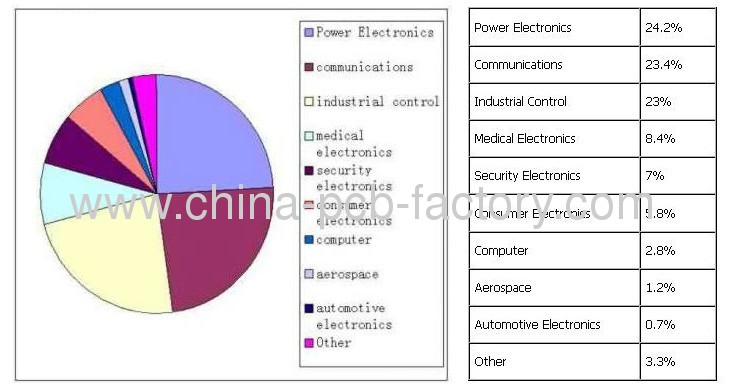

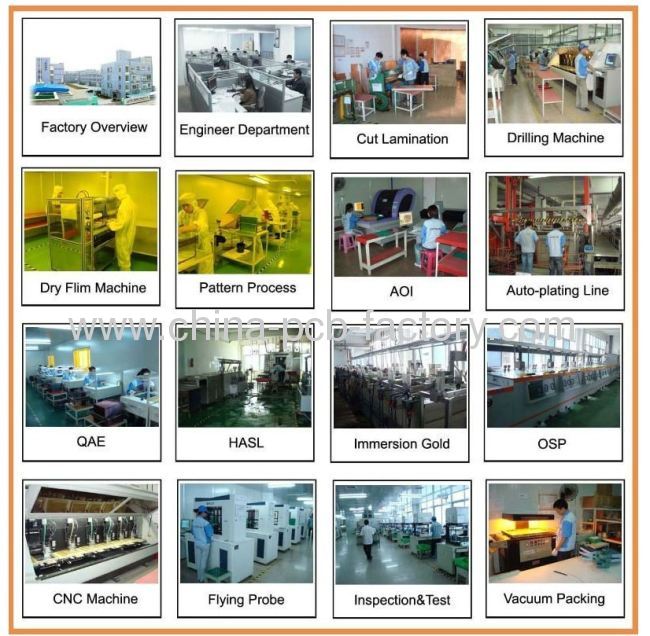

We are a Manufacturer & Supplier Specializing in Double Side PCB, Multi-Layer PCB, PTFE PCB, Ceramic PCB, Rogers PCB, Aluminum PCB. Meanwhile, we provide PCBA (Assembly) and ODM, OEM service. We are specializes in a full SMT and through hole PCBA assembly, obtaining components, building prototype quantities, and testing.

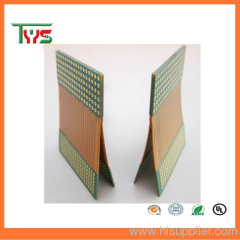

We supply all kinds of flex PCB

We supply all kinds of flex PCB

Specifications:

1) Min. Trace width: 0.004"

2) Min. Space between trace: 0.004"

3) Min. Hole size: 0.012"

4) Thickness tolerance:

A) Single sided: 0.005"

B) Double sided: 0.010"

5) Base materials: Polyimide and polyester

6) Conductor (copper thickness): 0.5oz., 10oz. And 20oz. (RA and ED copper)

7) Cover-layer: Polyimide and polyester (solder mask printing is available)

8) Adhesive material: Epoxy, acrylic and polyester

9) Stiffener materials: FR-4, mylar and polyimide

10) Surface finishes: Flash gold plating, selective gold plating and solder plating.

Quote requirement for pcb&pcb assembly:

----Gerber file and Bom list

----Clear pics of pcba or pcba sample for us

----Test method for PCBA

Detailed Terms for Pcb Assembly

1) Min. Trace width: 0.004"

2) Min. Space between trace: 0.004"

3) Min. Hole size: 0.012"

4) Thickness tolerance:

A) Single sided: 0.005"

B) Double sided: 0.010"

5) Base materials: Polyimide and polyester

6) Conductor (copper thickness): 0.5oz., 10oz. And 20oz. (RA and ED copper)

7) Cover-layer: Polyimide and polyester (solder mask printing is available)

8) Adhesive material: Epoxy, acrylic and polyester

9) Stiffener materials: FR-4, mylar and polyimide

10) Surface finishes: Flash gold plating, selective gold plating and solder plating.

Quote requirement for pcb&pcb assembly:

----Gerber file and Bom list

----Clear pics of pcba or pcba sample for us

----Test method for PCBA

PCB Assembly Capabilities

| Quantity | Prototype&Low Volume PCB Assembly,from 1 Board to 250,is specialty,or up to 1000 |

| Type of Assembly | SMT,Thru-hole |

| Solder Type | Water Soluble Solder Paste,Leaded and Lead-Free |

| Components | Passive Down to 0201 size BGA and VFBGA Leadless Chip Carriers/CSP Double-sided SMT Assembly Fine Pitch to 0.8mils BGA Repair and Reball Part Removal and Replacement |

| Bare Board Size | Smallest:0.25*0.25 inches Largest:20*20 inches |

| File Formate | Bill of Materials Gerber files Pick-N-Place file |

| Types of Service | Turn-key,partial turn-key or consignment |

| Component packaging | Cut Tape,Tube,Reels,Loose Parts |

| Turn Time | Same day service to 15 days service |

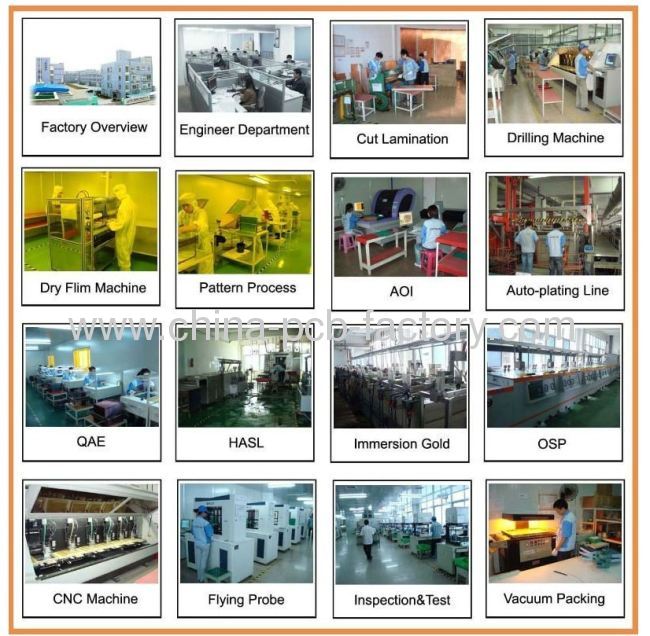

| Testing | Flying Probe Test,X-ray Inspection AOI Test |

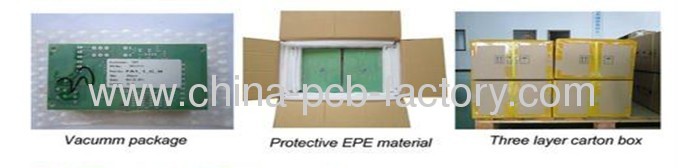

| PCB assembly process | Drilling-----Exposure-----Plating-----Etaching & Stripping-----Punching-----Electrical Testing-----SMT-----Wave Soldering-----Assembling-----ICT-----Function Testing-----Temperature & Humidity Testing |

Detailed Terms for Pcb Assembly

Technical requirement for pcb&pcb assembly:

---- Professional Surface-mounting and Through-hole soldering Technology

---- Various sizes like 1206,0805,0603 components SMT technology

----ICT(In Circuit Test),FCT(Functional Circuit Test) technology.

----PCB Assembly With UL,CE,FCC,Rohs Approval

----Nitrogen gas reflow soldering technology for SMT.

----High Standard SMT&Solder Assembly Line

---- High density interconnected board placement technology capacity.

---- Professional Surface-mounting and Through-hole soldering Technology

---- Various sizes like 1206,0805,0603 components SMT technology

----ICT(In Circuit Test),FCT(Functional Circuit Test) technology.

----PCB Assembly With UL,CE,FCC,Rohs Approval

----Nitrogen gas reflow soldering technology for SMT.

----High Standard SMT&Solder Assembly Line

---- High density interconnected board placement technology capacity.

Quote requirement for pcb&pcb assembly:

----Gerber file and Bom list

----Clear pics of pcba or pcba sample for us

----Test method for PCBA

----Gerber file and Bom list

----Clear pics of pcba or pcba sample for us

----Test method for PCBA

Why us?

Quality

Our UL/Rohs standards insure quality assemblies from start to finish. Whether it's a simple custom product or a complex turnkey production run, Moko will adhere to the highest quality standards.

--------------------------------------------------------------------------------

Capable

Moko offers the latest in assembly capabilities and qualifications insuring that quality is built into every product we produce.

--------------------------------------------------------------------------------

Experience

When it comes to your build you want a partner you can depend on. Our management team has over 8years of combined industry knowledge. Our engineering team has over 5 years experience.

--------------------------------------------------------------------------------

Protecting your interests

Protecting your Intellectual Property is job one! Our staff of trained professionals are all working under a strict confidentiality contract and treat your important documentation as they would their own.

--------------------------------------------------------------------------------

Flexibility

We pride ourselves on our ability to custom tailor programs around our customers' needs. We take time to listen to your unique business needs and then set out to surpass them

Item | Manufacture Capability | |

Material | FR-4 / Lead free Materials (RoHS Compliant) /CEM-3, Aluminium, Metal based | |

Layer No. | 1-12 | |

Finished Board thickness | 0.2 mm-3.8mm'(8 mil-150 mil) | |

Board Thickness Tolerance | ±10% | |

Cooper thickness | 0.5 OZ-2OZ | |

Copper Plating Hole | 18-40 um | |

Impedance Control | ±10% | |

Warp&Twist | 0.70% | |

Peelable | 0.012"(0.3mm)-0.02'(0.5mm) | |

Images | ||

Min Trace Width (a) | 0.1mm (4 mil) | |

Min Space Width (b) | 0.1mm (4 mil) | |

Min Annular Ring | 0.1mm (4 mil) | |

SMD Pitch (a) | 0.2 mm(8 mil) | |

BGA Pitch (b) | 0.2 mm (8 mil) | |

Solder Mask | ||

Min Solder Mask Dam (a) | 0.0635 mm (2.5mil) | |

Soldermask Clearance (b) | 0.1mm (4 mil) | |

Min SMT Pad spacing (c) | 0.1mm (4 mil) | |

Solder Mask Thickness | 0.0007"(0.018mm) | |

Holes | ||

Min Hole size (CNC) | 0.2 mm (8 mil) | |

Min Punch Hole Size | 0.9 mm (35 mil) | |

Hole Size Tol (+/-) | PTH:±0.075mm;NPTH: ±0.05mm | |

Hole Position Tol | ±0.075mm | |

Plating | ||

HASL | 2.5um | |

Lead free HASL | 2.5um | |

Immersion Gold | Nickel 3-7um Au:1-5u'' | |

OSP | 0.2-0.5um | |

Outline | ||

Panel Outline Tol (+/-) | CNC: ±0.125mm, Punching: ±0.15mm | |

Beveling | 30°45° | |

Gold Finger angle | 15° 30° 45° 60° | |

Certificate | ROHS, ISO9001:2008, SGS, UL certificate | |

BLANK PRINTED CIRCUIT BOARD

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Printed Circuit Board

Rigid Printed Circuit Board

Printed Circuit Board Assembly

Flexible Printed Circuit Board

Multilayer Printed Circuit Board

Hdi Printed Circuit Board

More>>