|

Shenzhen Tianweisheng Electronic Co., Ltd.

|

Gold Index: 77311

You are here: home > Hot Products > Range hood circuit electronic pcba

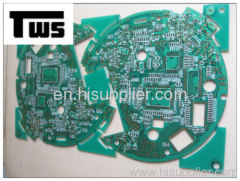

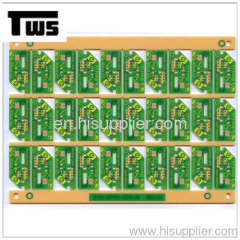

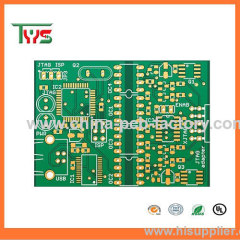

Range hood circuit electronic pcba

| Price: | 57.0~200.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU, |

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Model No.:

7410klo

Production Capacity:

1000square meter/per day

Delivery Date:

3~10days

Independence tolerance:

+/-18%

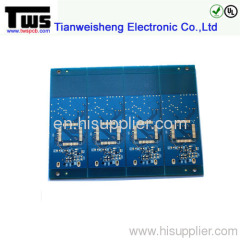

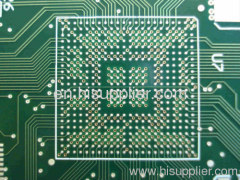

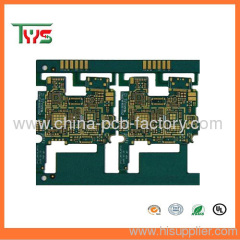

Layer count:

1-24

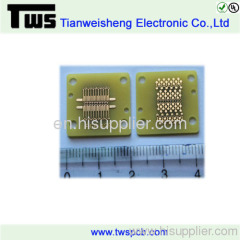

Gold finger:

Ni: 80~250u", Au: 1~5u"

Via plug:

Max via size: 24mil (0.6mm)

Certification:

UL/SGS/ROHS

Means of Transport:

Ocean,Land,Air,

Packing:

Inner vacuum and plastic pa...

Max pane size:

34"*25"

Aspecr Ratio:

10:7

Solder mask abrasion:

≥10H

Warp and twist:

≤0.55%

Peel Strength:

1.4N/mm

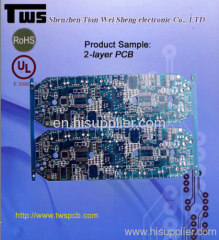

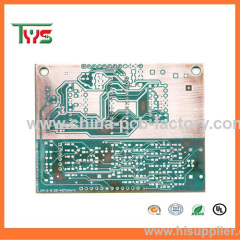

1.Base Material:Aluminum pcb

2.copper thickness:0.5OZ

3.board thickness:1mm

4.Surface treatment:HASL

5.layer:1~18

Specifications

****Brief description:

1) Gas Hood/cooker hoodcontroller

2) Three air blowing speed options

3) LED lightingfunction

1) Gas Hood/cooker hoodcontroller

2) Three air blowing speed options

3) LED lightingfunction

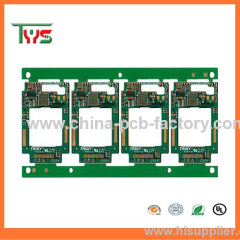

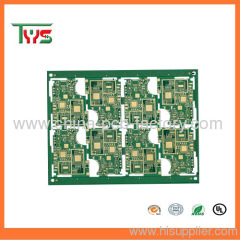

***Function details:

1) Four hobs controller

2) Touch button screen.

3)Safety child lock function.

4) Timing function

5) Comply with RoHS & REACH standard

6) Passing EMC & LVD test, applicable to counties where the voltage is

unstable

7) Lead Free

*** YINGKE SMT ProductionFlow:

Material Receiving&IQC→ Stock → Materialto SMT→ Solder Paste/Glue Printing → Chip Mount → Reflow → 100% VisualInspection → Automated Optical Inspection (Precision AOI machine) → QC Sampling→ SMT Stock → Material to PTH → Plated Through Hole on production line → WaveSoldering → Touch Up → 100% Visual Inspection→ In-Circuit Test (ICT) → FinalAssembly → Functional Test (FCT) → Packing → Storage → Shipping

*** Requested information for PCBassembly:

1. Gerber file &Bom list ifpossible

2. PCB sample

3. Testing method & Testingfixture

4.Quantity

***Research & Technology capability

1) Over 50 engineers, including hardware engineer & software engineer, who can offer technical assistant for developing your new projects, or improving your old products.

2) EMC test room and all other kinds of test machine to ensure the quality for each design.

3) High efficiency to shorten the sample lead time. Normally it will take 4 weeks on developing one PCBA for small home appliance, and 8-10 weeks on developing the PCBA for the white goods, such as PCBA for washing machine, refrigerator, and air conditioner.

Advanced ProductionEquipment

Product HighQuality Perfect

Meet your need is ourgreatest pursuit .If you are looking for a pcb board manufacturerinchina,Pleasegive us your files ofpcb for a quote (Gerberfiles and specification),I will reply email in 3hours. Youalso cancontact usby .

1.Advanced production lines andprofessional staff.

2.Honesty credibility in china'stop.

3.Competest price but highquality.

4. One-stopservice.

5.Delivery ontime.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Range Hood

Electronic Circuit Board

Electronic Circuit Breaker

PCBA

Pcba Assembly

Pcb And Pcba

More>>

Find more related products in following catalogs on Hisupplier.com

Company Info

Shenzhen Tianweisheng Electronic Co., Ltd. [China (Mainland)]

Business Type:Manufacturer

City: Shenzhen

Province/State: Guangdong

Country/Region: China (Mainland)

You May Like:

Product (809)

- Hot Products (205)

- Rigid-Flex pcb (15)

- FR4 PCB (503)

- LED PCB (38)

- FPC (14)

- PCB Assembly (15)

- Others (19)

.gif)